Facility-wide 5S in progress: aisleways, ceilings, walls, columns, utilities cleaned and painted according to standard color scheme.

What Most Leaders Understand About 5S

Most people generally associate 5S with improving workplace housekeeping. Some understand that, “Cleaning Equipment for Inspection,” adds another dimension of improving uptime through detection of problems early so that remedial action can be implemented before equipment breaks down or quality defects can occur. And a few may also recognize that 5S implementation of Visual Management and a “Plan for Every Part” allows for the development of Standard Work and the ability of Management to assure pull via kanban (and therefore conformance to the manufacturing plan) is being met.

What Far Fewer Leaders Understand About 5S

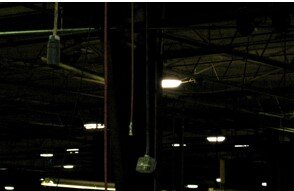

Same area as above, before facility-wide 5S…

In my experience, however, very few truly understand the value of the complete physical and cultural transformation that can result from facility-wide 5S, including painting their plant walls, ceilings, utility piping and epoxy coating their floors with clearly marked aisles (separating pedestrian and forklift traffic), increasing lighting levels to make the environment brighter, providing a plant address system for improved location communication (stock storage locations, safety issue notification & tracking, etc.).

There is tremendous value of using the 5S process to strongly signal to the workforce that Management is committed to driving change and is willing to, “put their money where their mouths are.”

In every Lean Transformation that I’ve been fortunate enough to lead or be a part of, facility-wide transformation was always on my “short list” of things to do. However, it is important to understand that the investment in this aspect of transformation is not insignificant, and must be planned over time. Additionally, it is not unusual for such facility investments to encounter resistance because of the lack of immediate, demonstrable payback.

Let’s talk about “Why” facility-wide 5S is something I believe in wholeheartedly, and why making these investments matters.

What is it like working in a facility that doesn’t have 5S?

Clutter creates Safety hazards…

Think for the moment of going to work every day in a dark, dirty, cluttered facility, where you are constantly hunting for tools, materials, and information. Every time you walk through your work area, you must be hypervigilant to avoid trip hazards, moving equipment and forklifts.

Lighting prior to facility-wide 5S…

And if part of your job is to ensure that the equipment is operating correctly and that quality requirements are being met… checking to ensure your equipment is working properly is a challenge, and attempting to find quality defects is next to impossible when you are literally being kept, “in the dark.”

What happens when facility-wide 5S is implemented?

The responses that come from the workforce are always, “Thank you,” and, “you said that ‘things around here are going to change’ and you meant it!“

Safety, Quality, and Productivity all improve as a result of having facility-wide 5S in place. The investments in the facility help build trust, and demonstrate both a longer-term vision and respect for the people who work there. Additionally, any other “lean” changes that are introduced soon begin to have far less “push back” from the floor, as the workforce has far greater excitement and interest in participating in Kaizen.

While it may be difficult to nail down the exact financial payback, consider for a moment… how much is this worth?

©2020 Dawn Armfield, ValueFlo Consulting LLC